M&S Pipe fittings

M&S bends are used to change the direction in hygienic pipe sections in the food, chemical, cosmetic and pharmaceutical industries.

For special applications, bends are available in orbital weldable version and in different hygienic classes.

Depending on the area of application, the operating conditions and the hygienic requirement, the right version, a suitable material and the required quality must be selected.

Features

- Very extensive stock programme in different versions, dimensions and qualities according to standard

- Manufactured from longitudinally welded pipes in annealed (BC*) or non-annealed version (CC)

- Compliance with angle and dimensional tolerances as well as ovality specifications guarantee welding without stresses and offsets

- Versions for the production of piggable piping systems are available

Same product - different applications

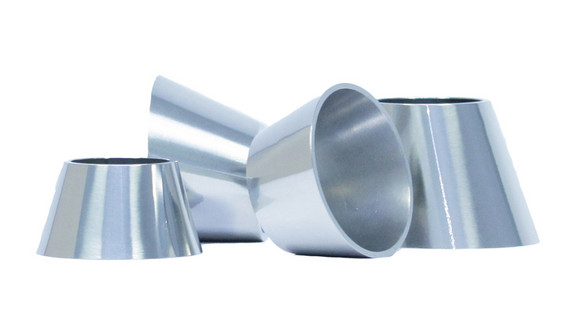

Reducers

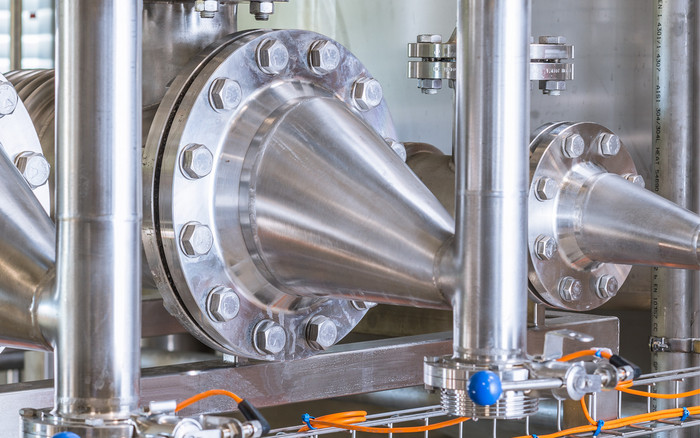

Reductions are used to change the nominal width within a piping system. They are available in two basic designs: concentric and eccentric. The fittings are generally welded directly into the pipeline. The reducers for welding are standardised in DIN 11852. In addition to the reducers with weld-on ends, M&S also has welded combinations of various fittings with connection fittings, e.g. milk pipe fitting parts or clamping sockets.

- Reduction RK (concentric)

- Reduction RE (eccentric)

- Reducers with standardised connections (e.g. thread, taper or TC (clamp))

- Transitions from different process connections

- Transitions of different pipe series (e.g. inch-DIN)

- Optionally other surfaces in contact with product and not in contact with product

Arc

Bends are used to change the direction within a pipeline run. The standard angle of the bends is 90°. The M&S range also includes 45° and 180° bends. Pipe bends are manufactured by forming welded stainless steel pipe. They are standardised in DIN 11852. A bend is defined by an outer diameter, a wall thickness and a radius of curvature.

- Bend BS 45° - 90° - 180°

- Bend BL 45° - 90

- Bend BA5 90°

- Elbows with standardized connections (e.g. thread, cone or TC (clamp))

- Arc for orbital welding

- Optionally other surfaces in contact with product and not in contact with product

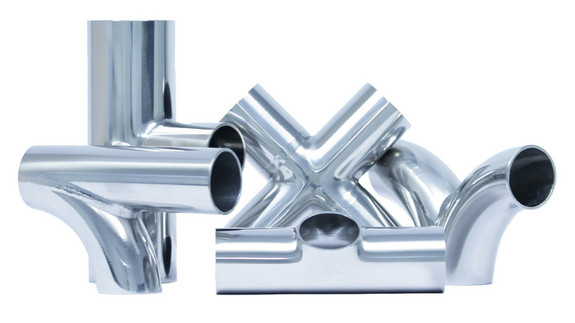

T-pieces and T-bends

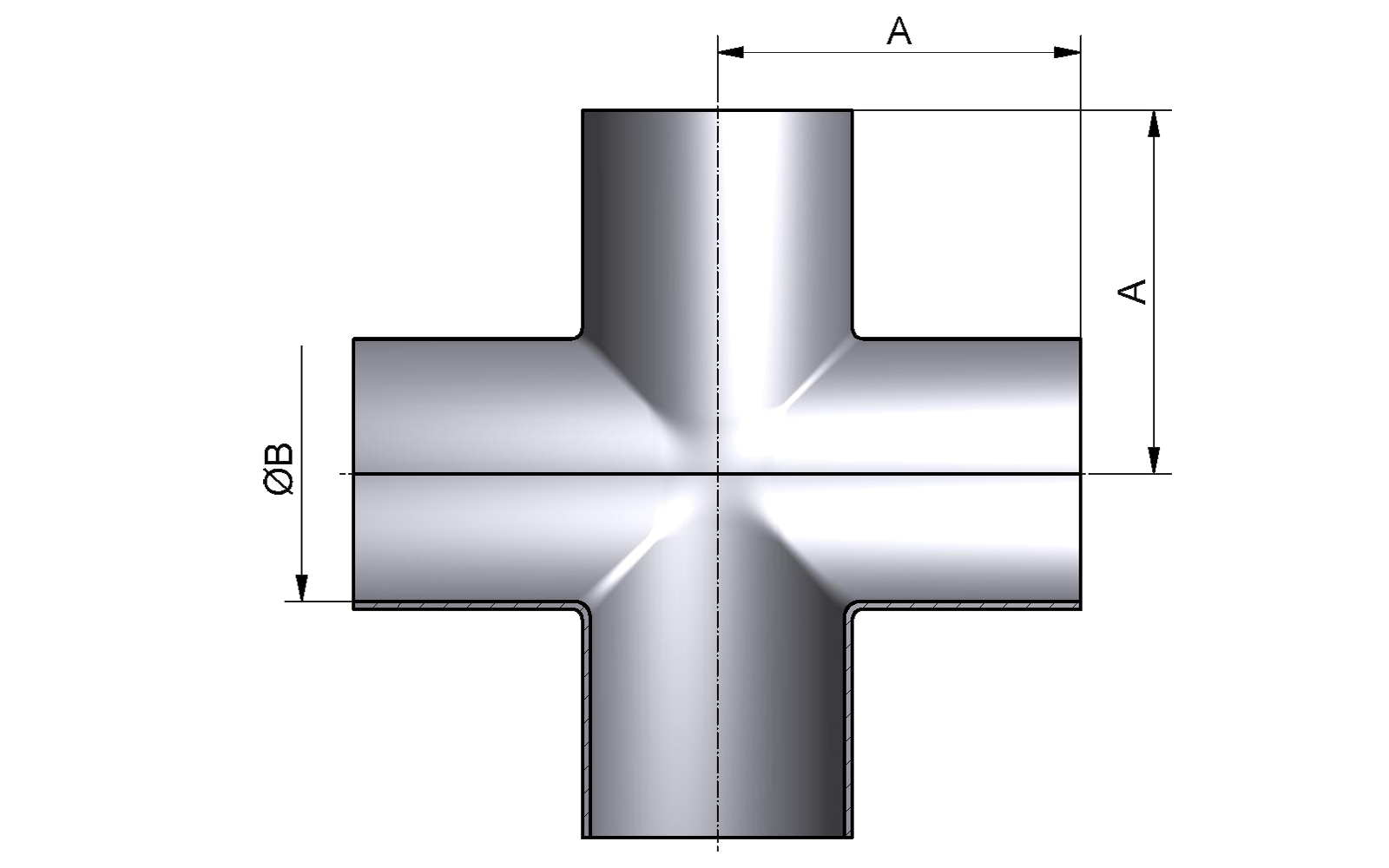

T-pieces are used to divide the flow within a pipe run. They are available in long and short versions. If the branch has a smaller nominal width than the main passage, it is referred to as a reducing tee. As a special form of T-piece, there is also the cross piece, in which there are outlets on both sides of the main passage. The T-bend and double T-bend (Y-bend) are flow-optimised pipe fittings and are used for flow division and flow combination. T-pieces are standardised in DIN 11852.

- T-pieces TK (short and equal version)

- T-pieces RTK (short and reduced version)

- T-pieces TS (long and even version)

- T-pieces RTS (long and reduced version)

- Cross pieces (short and long) - Optionally reduced

- Tees with standardized connections (e.g. thread, taper or TC (Clamp)

- Optionally other surfaces in contact with product and not in contact with product

- T-bend and double T-bend