Special production

Do you actually know what we can really do?

Very often, in addition to standard products, high-quality special parts are also required, which can consist of modifications, combinations or even complex prefabrications of plant components. Here, as a manufacturer of quality products, it is advantageous not only to have the required components in stock, but also the necessary manufacturing experience and the appropriate machinery.

Examples of special part production of the highest quality with extensive documentation are valve clusters, which are used in fully automatic systems and are required to work exclusively with pneumatic actuators. Panels are comparable to a nodal point and are used to divert liquids in a production plant in a space-saving manner. Manifolds are used to distribute flowable media. They have one inlet and several outlets.

This is only an excerpt of the extensive special solutions that we regularly manufacture for our customers.

Individual products are standard products for M&S. The maximum adaptation of standard valves to the specific needs of our customers is a daily challenge for us. No matter whether it is a large series or a single piece.

Challenge us !

Tank connection

My profile

- Material 304L – outside surface = mat blasted

- Inside surface = welding seam pickled

- Total length = 523 x 446 mm

- Connections = welding connection DN 125 and male part DN 100

- Documentation = inspection certificate 3.1 on raw material

- Customized production

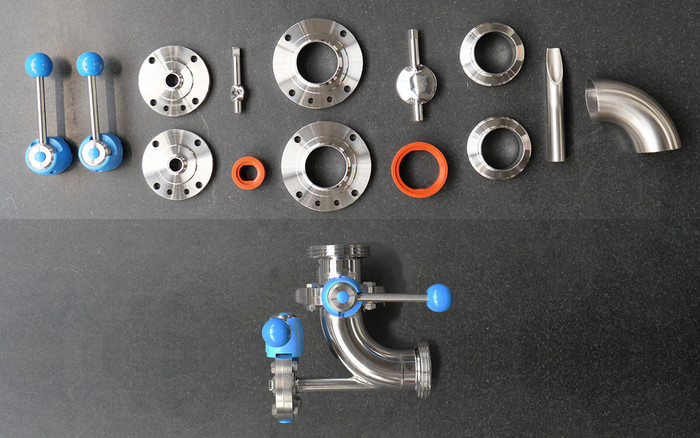

Valve unit SV04

My profile

- Material 316L – outside surface = electropolished

- Inside surface = pickled – welding seams ground

- Overall length = 195 x 155 mm

- Connections = passage male DN 50 – outlet welding end DN 15

- Documentation = certificate 3.1 on primary material

- Customized production

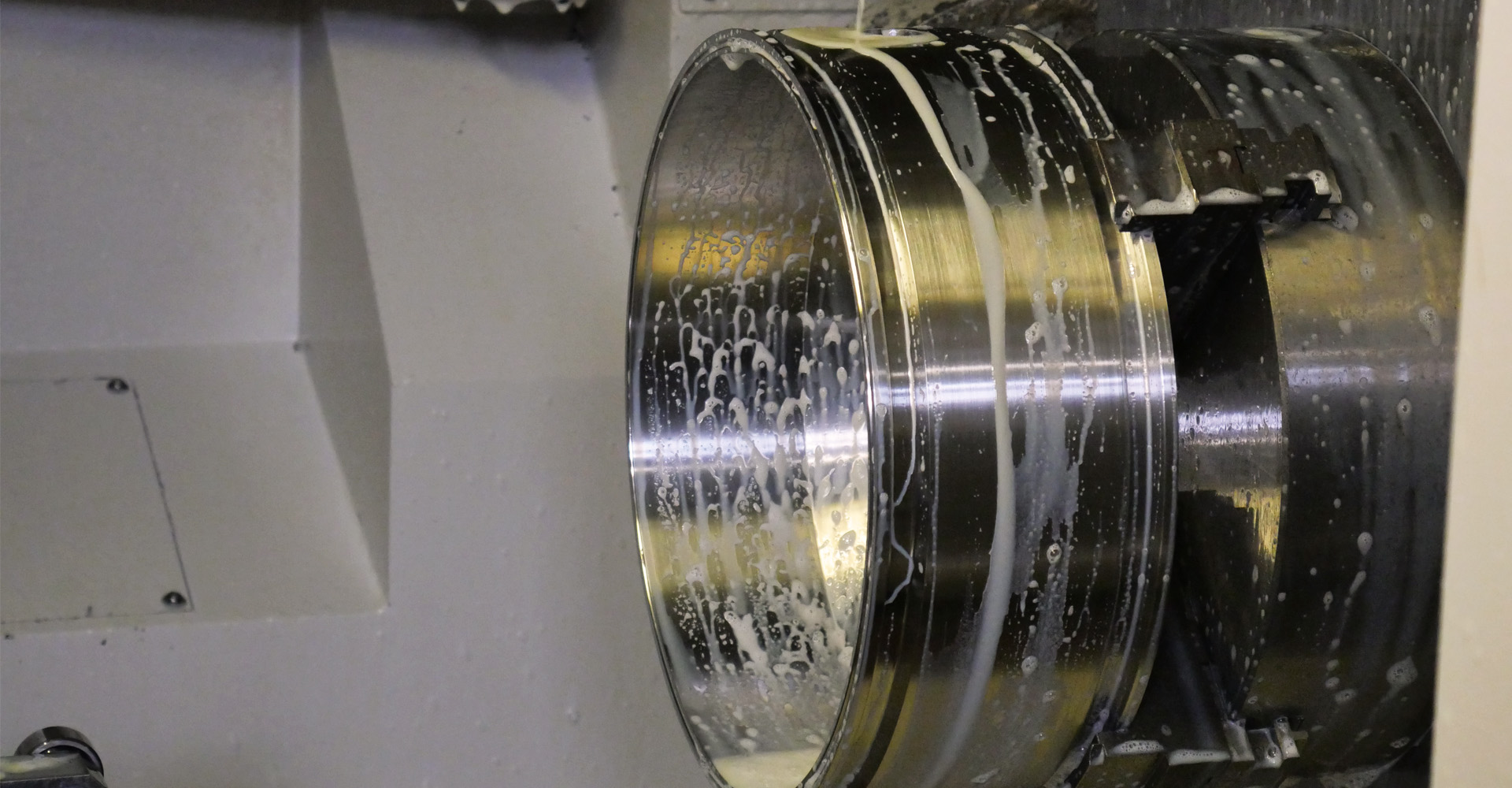

Cooling tank

My profile

- Material 304L - Surface outside = electropolished

- Surface inside = welds ground and electropolished

- overall length = 360 mm

- Connections = top TC connection DN 125 - side threaded connection DN 10

- Documentation = APZ 3.1 on the primary material

- Customized production

Please send us an e-mail with your requirements - ideally with a drawing or a dimensioned sketch - so that we can prepare a quotation for you straight away.