M&S pipe connections

M&S pipe connections are used for the detachable connection of pipelines as well as for the connection of machines, apparatus and containers.

They are available as screwed, clamp or flange connections and are manufactured in accordance with the applicable standards. Basically, they are made of forged primary material at M&S.

Depending on the operational requirements, the operating conditions and the hygienic demand, a suitable and appropriate pipe connection must be selected.

Features

- Simple to high hygienic requirements

- Screwed pipe connections

- Easy detachable with a tool

- For medium pressures and temperatures

- When opened, impermissible overpressure can be relieved more safely

- Flange connections

- Detachable with a tool

- For higher pressures and temperatures

- When opened, impermissible overpressure can be relieved more safely

- Clamp connections

- Very easy detachable without tools

- When opened, impermissible overpressure can escape abruptly

- Hose connections

- Can be detached with or without tools, depending on the process connection

- Screwed pipe connections

- Without hygienic requirements:

- Industrial fittings

- Can only be detached with a tool

- Industrial fittings

Same product - different applications

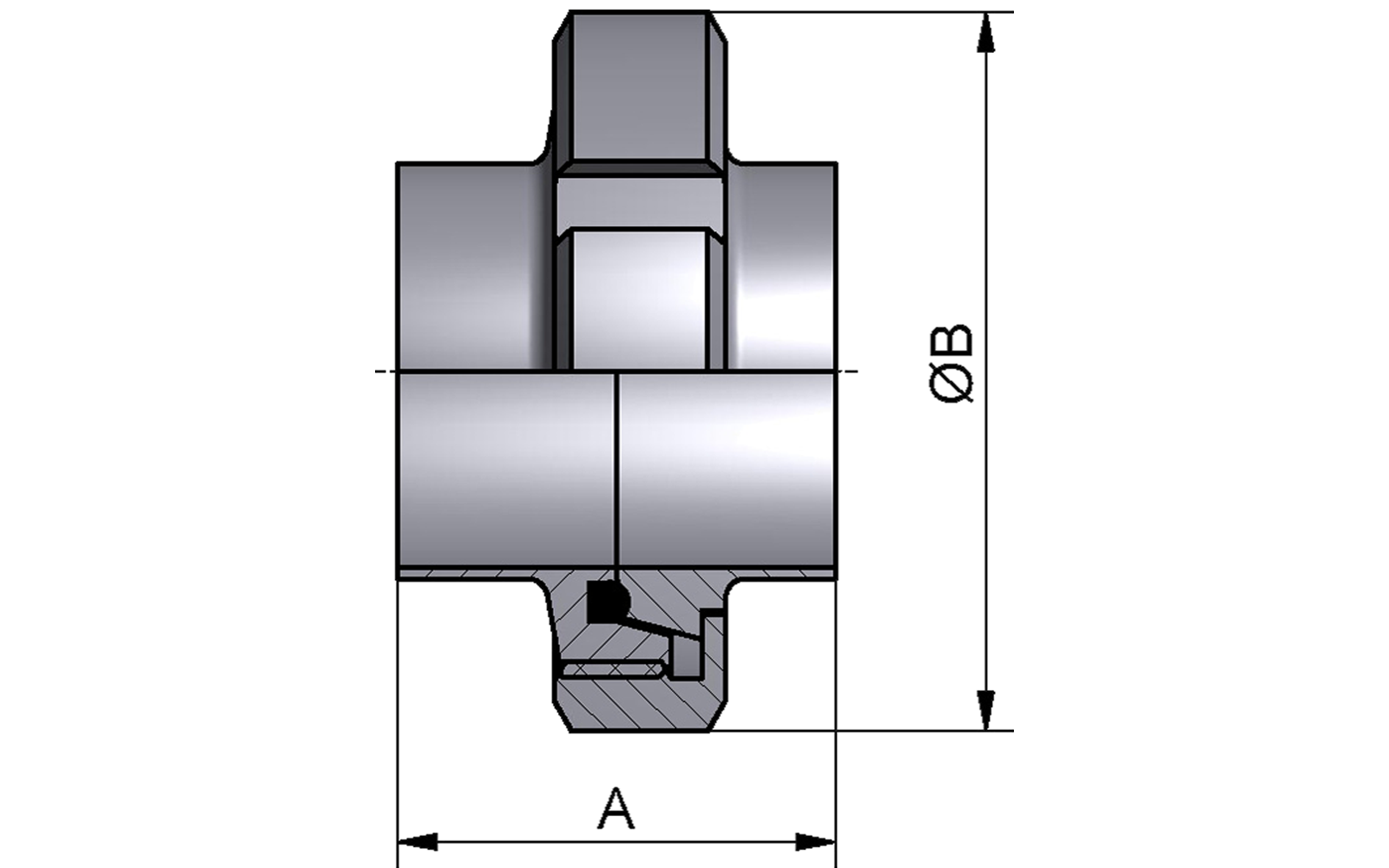

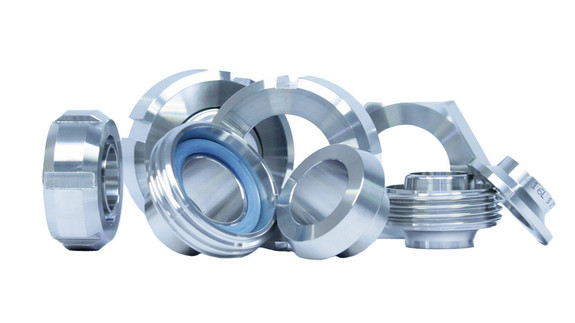

Screwed pipe connection

Screwed pipe connection DIN 11851 (milk pipe fitting) for hygienic requirements by means of sealing by shaped gasket.

Alle screwed connections

- Easy detachable with tools

- For medium pressures and temperatures

- When opened, impermissible overpressure can be relieved more safely

Variants

- Screwed pipe fitting DIN 11851 (milk pipe fitting)

- For pipes according to DIN EN 10357, other dimensional ranges available: Inch, ISO

- Pipe connections for welding and for expanding (roll-in)

- SMS screwed connection for pipes according to DIN EN 10357 – short connections

- DS screwed connection for pipes according to DIN EN 10357 – short connections

- RJT screwed connection for pipes according to DIN EN 10357 – short connections

- IDF screwed connection for pipes according to DIN EN 10357 – short connections

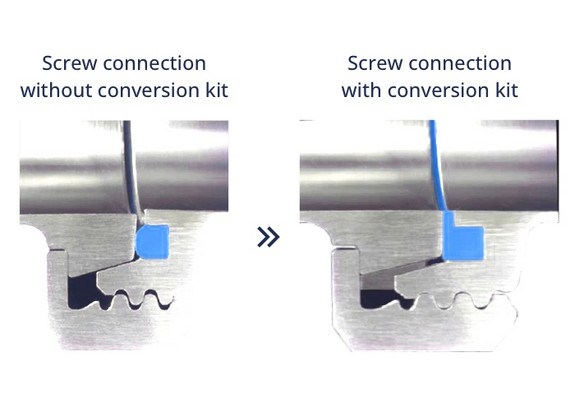

NEW

Pipe fitting DIN 11851

Efficient retrofitting: Quick and effective optimisation of conventional dairy pipe fittings.

Cost-effective alternative: Replacement for pipe fittings to DIN 11864 / DIN 11853.

Precise alignment: Offset-free integration into existing pipe systems.

Defined preload: Created by stop function for optimum sealing.

Hygienic sealing: Flush and reliable sealing, comparable to DIN 11864 / DIN 11853 standards

- Innovative solution: Combination of a metal stop ring with a special M&S collar seal.

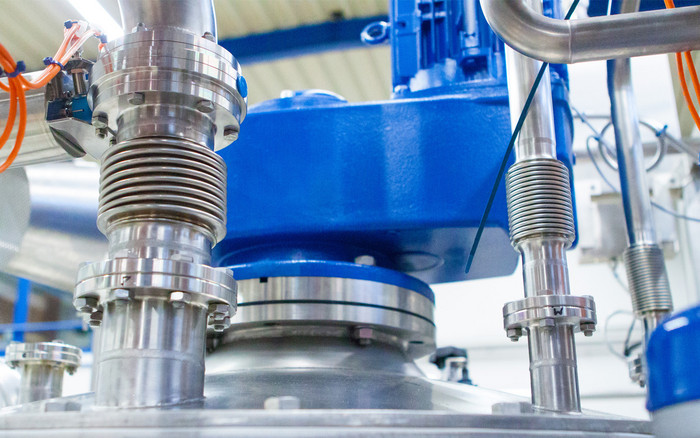

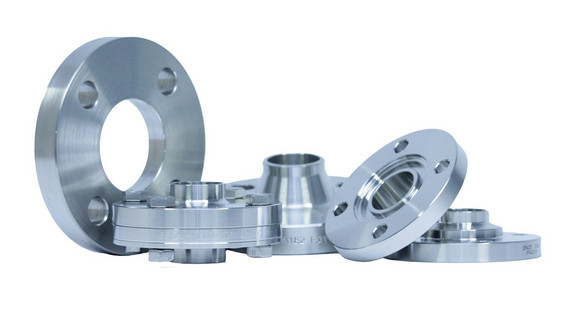

Flange connections

All flange connections

- Pressure resistant even at higher pressures (standard flanges are available in different pressure ratings) and temperatures (depending on the gasket material)

- When opened, impermissible overpressure can be relieved more safely

- Depending on the design, for simple to high hygienic requirements

Variants

- Small flange connections with shaped gasket for pipes according to DIN EN 10357

- Flange connections according to DIN EN 1092-1 for pipes according to DIN EN ISO 1127 and DIN EN 10357

- Welding neck flanges

- Flat and blind flanges

- Loose flanges with welding neck/collar

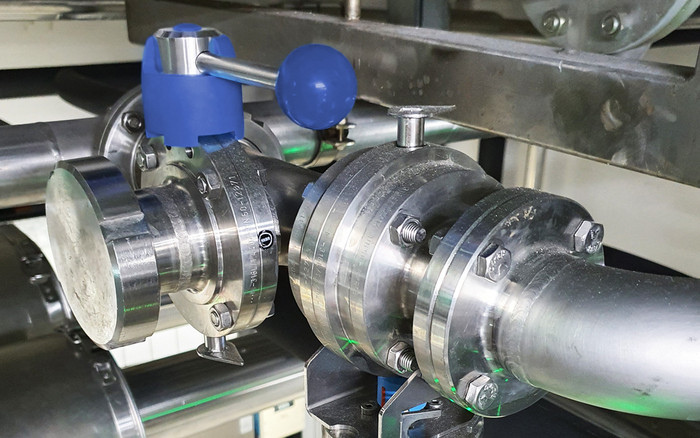

Clamp connections

Clamp connections according to DIN 32676

- Sealing with a profile gasket

- For normal hygienic requirements

- Very easy to detach without tools

Variants

- Clamp connection according to DIN 32676 for pipes according to DIN EN10357

- For pipe connection short (KK) and long (KL)