M&S Hygienic pipe fittings

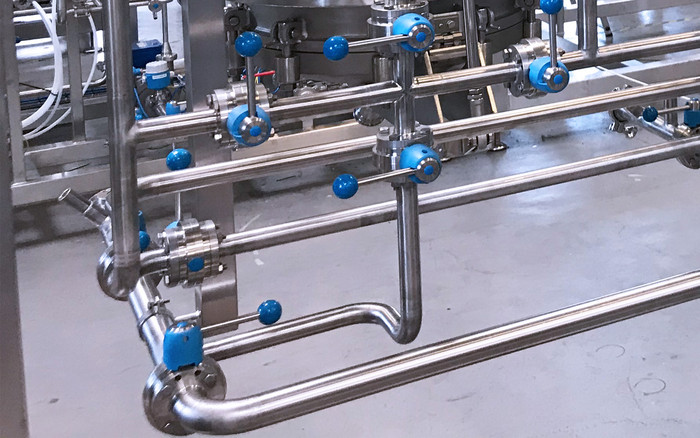

M&S bends DIN 11865 are used to change direction and M&S tees are used to divide the flow in hygienic piping systems for aseptic processes in plants, machines and apparatus in the cosmetic, pharmaceutical and chemical industries.

Both fittings are for orbital welding and are manufactured with different, high-quality inside and outside surfaces.

The range is completed by M&S reducers DIN 11865. Manufactured as turned parts in the hygienic sector, they are used as a transition between different diameters.

M&S manufactures two corresponding continuous product lines as standard, the PharmCom range (Pharmaceutical Components) in material 1.4435 and the HyCom range (Hygienic Components) in material 1.4404, and stock these in various hygienic classes.

M&S reducers DIN 11865 are used as transition between different diameters in hygienic piping systems for aseptic processes in plants.

M&S Hygienic pipe fittings

M&S bends DIN 11865 are used to change direction and M&S tees are used to divide the flow in hygienic piping systems for aseptic processes in plants, machines and apparatus in the cosmetic, pharmaceutical and chemical industries.

Both fittings are for orbital welding and are manufactured with different, high-quality inside and outside surfaces.

The range is completed by M&S reducers DIN 11865. Manufactured as turned parts in the hygienic sector, they are used as a transition between different diameters.

M&S manufactures two corresponding continuous product lines as standard, the PharmCom range (Pharmaceutical Components) in material 1.4435 and the HyCom range (Hygienic Components) in material 1.4404, and stock these in various hygienic classes.

M&S reducers DIN 11865 are used as transition between different diameters in hygienic piping systems for aseptic processes in plants.

Features

- Complete self-contained programmes consisting of different pipe connections and pipe fittings in the same material quality, the same hygienic class and in an orbital weldable design. Can be optionally supplemented with various process valves of the same quality.

- PharmCom product range

- Material 1.4435

- Delta-ferrite content < 0,5%

- HyCom product range

- Material 1.4404

- Delta-ferrite content < 3,0%

- PharmCom product range

- Documentation optional

- Inspection certificate 3.1 according to DIN EN 10204 for the primary material

- Inspection certificate 3.1/AD2000-W2 according to DIN EN 10204

- Other inspection certificates according to DIN EN 10204 (e.g. for surface roughness)

Same product - different applications

Reducers

Reducers are used to change the nominal size within a piping system. They are available in two basic designs: concentric (RK) and eccentric (RE). In the hygienic sector, the reducers are always turned.

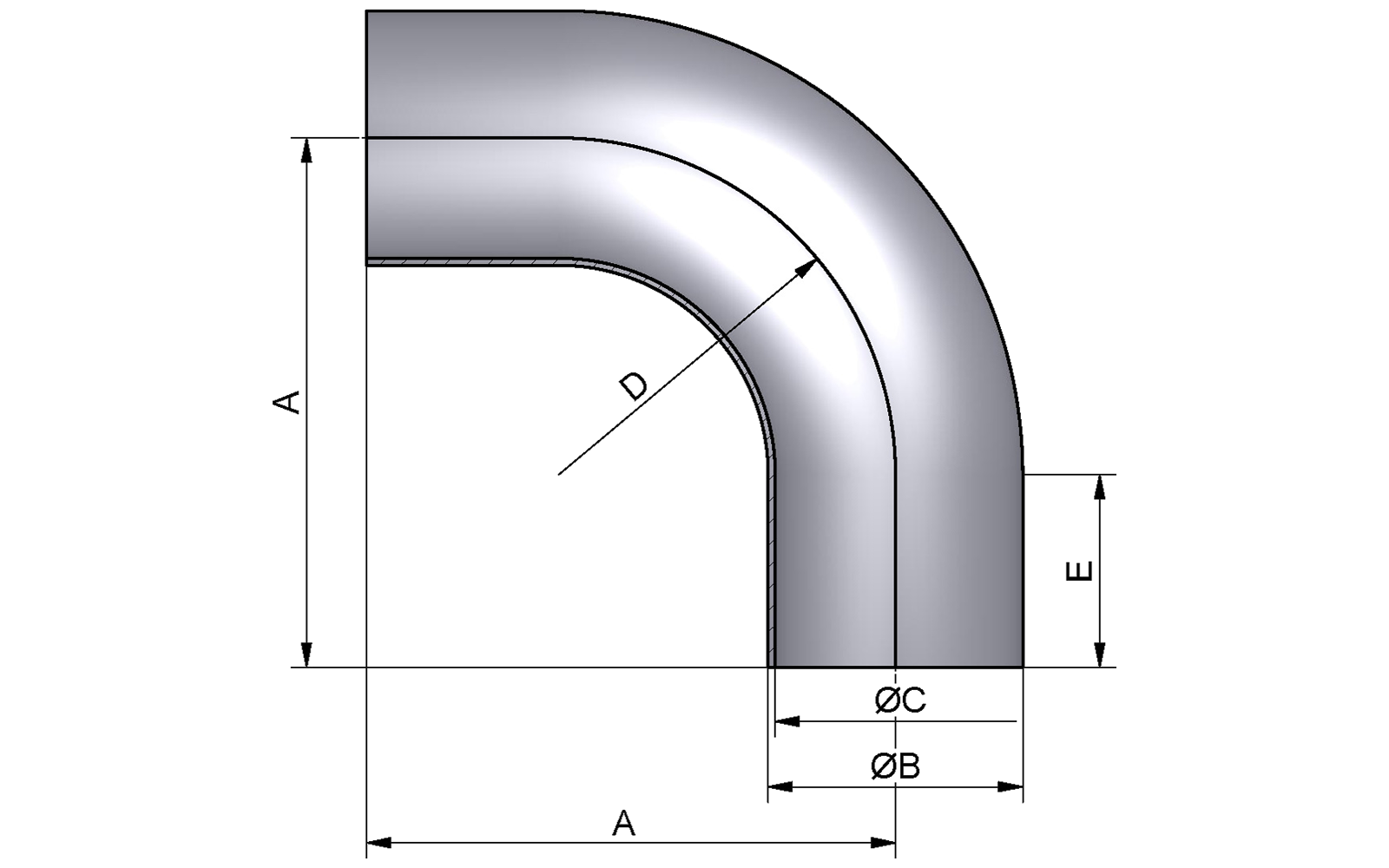

Bends

Bends are used to change the direction within a pipe run. The standard angle of bends is 90° and 45°. Bends are made by forming welded stainless steel pipe. A bend is defined by an outer diameter, a wall thickness and a radius.

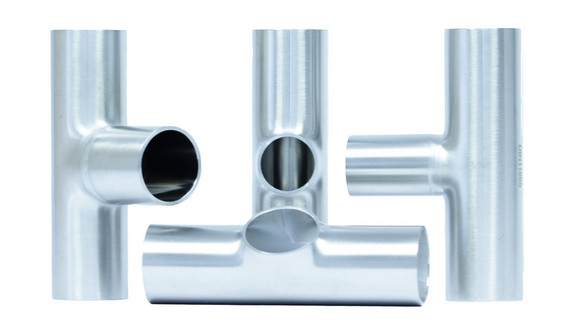

Tees and T-bends

Tees are used to divide the flow within a pipe run. They are available in long and short versions. If the outlet has a smaller nominal diameter main passage, it is called a reducing tee.