Hose connections

M&S hose connections are used for the transition from pipes to flexible hose lines. They are equipped with a variable process connection consisting of a pipe connection from the M&S range and a hose nozzle for integrating the hose.

Depending on the operational requirements, the operating conditions and the hygienic demand, a suitable and appropriate design of the hose connection must be selected.

Usage

- For transition from rigid pipelines to flexible hose lines:

- As connection of hoses to tank trucks or mobile pumps.

- To compensate vibrations and decouple rigid connections, e.g. for apparatus and containers on load cells.

Features

- Simple to high hygienic requirements (depending on process connection and hose integration.

- Hose connection force-locked with pressing sleeve.

- For normal hygienic requirements.

- Slightly reduced passage.

- Very secure hose connection (hydraulic crimping only by specialist dealers).

- Hose nozzle with half-shells force-locked.

- For simple hygienic requirements.

- Reduced passage.

- Safe hose binding (mechanical on-site pressing by specialist personnel).

- Hose nozzle with hose clamp force-locked.

- Reduced passage.

- No hygienic requirements.

- Simple hose binding.

- Hose connection force-locked with pressing sleeve.

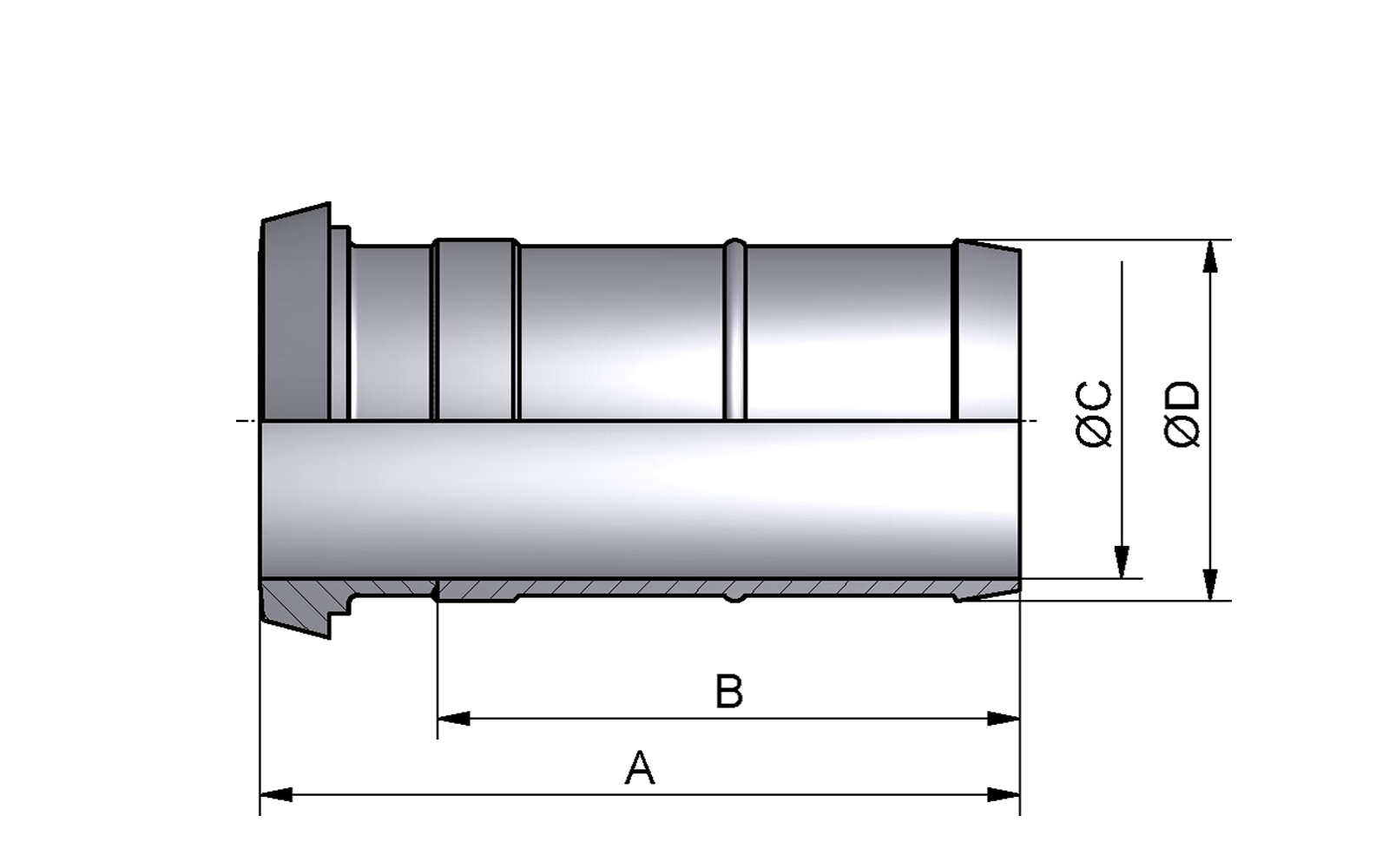

Hose nozzles - Variants

Different applications, products and processes in various industries ensure a wide range of hose designs and corresponding connection parts. M&S manufactures a large part of this extensive range of hose connections. In addition to the standard designs, many other variants are produced, also according to customer specifications. Hose connectors are available in smooth, scaled or beaded design.

Hose nozzles M&S version

Hose nozzles without safety collar in solid design or as pipe design for welding or with following connections:

- Pipe connection DIN 11851

- Clamp- (TC) ferrule DIN 32676

- Pipe connection DIN 11853

- Pipe connection DIN 11864

Hose nozzles with safety collar

Hose nozzles with safety collar according to EN 14420 for welding or with following conncetions:

- Pipe connection DIN 11851

- Clamp- (TC) ferrule DIN 32676

- Pipe connection DIN 11853

- Pipe connection DIN 11864

Half shells or clamping sleeves

Pressing sleeves, shells and clamping jaws according to EN 14420 for safe and tight connection of suitable hoses.

- Pressing sleeves for professional binding

- Shells and clamping jaws for on-site binding