M&S vacuum valves

M&S vacuum valves are used for vacuum protection in hygienic containers, apparatus and machines.

They are closed when not in use and only open when the pressure falls below the set differential pressure compared to atmospheric pressure. After the negative pressure has been compensated, the valve closes and the system can continue to be operated. The valves are of spring-loaded or weight-loaded design.

M&S manufactures a wide range of valve types and sizes that can be selected to suit the requirements. Optionally, they can be equipped with pneumatic lifting, CIP device, position feedback and valve heating.

Features

- Suspended vacuum valve type 9224

- Vertical installation

- Hygienic design with CIP collection tray

- Very easy to clean by means of built-in spray ball

- Idle, with valve seat at bottom level

- Cleaning of the valve seat by means of pneumatic lifting optional;

- Heating with heating cartridge optional

- Feedback of switching position optional

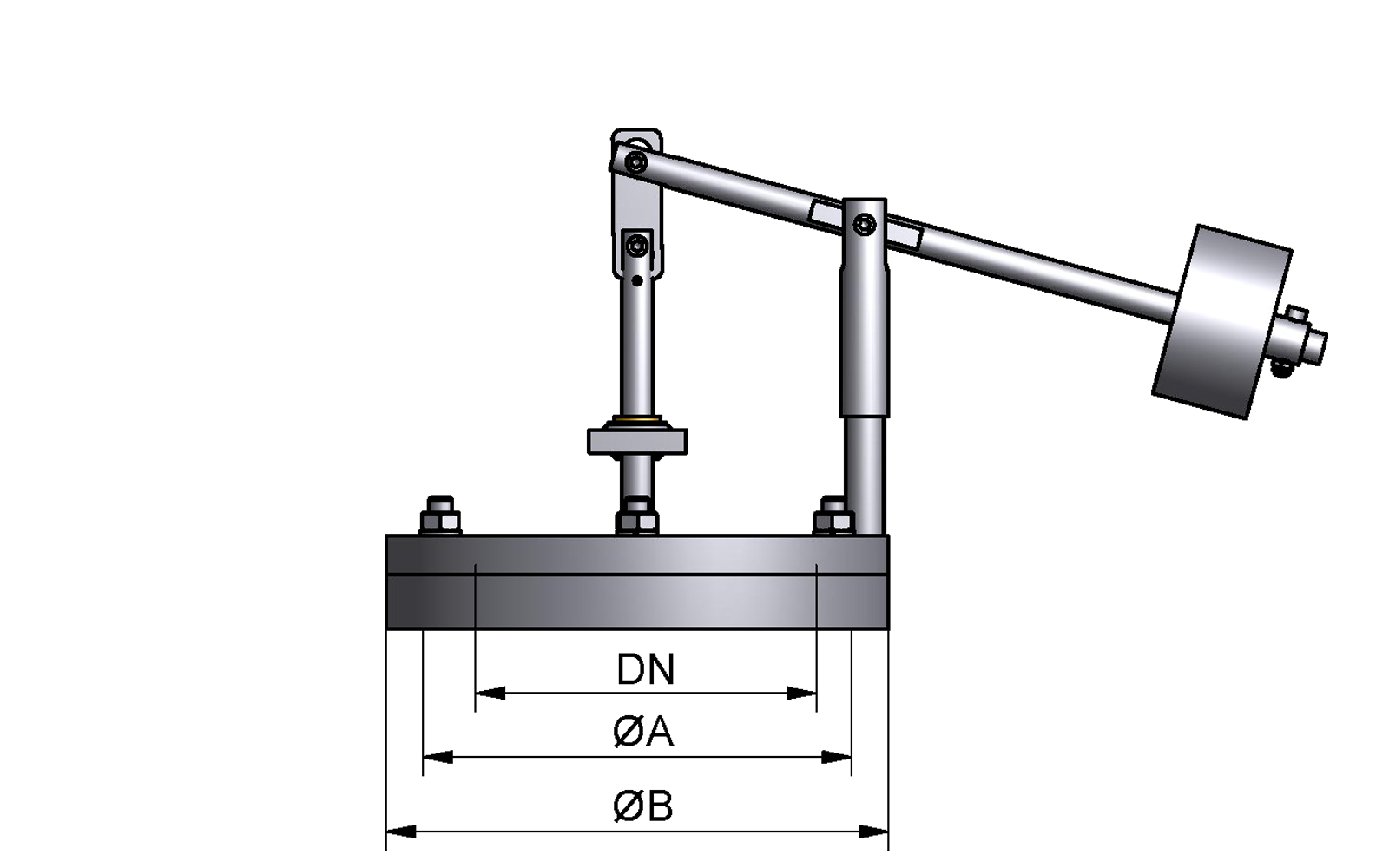

- Weight-loaded vacuum valve type 92250

- Vertical installation

- Weight-loaded

- Connection flange according to DIN EN 1092-1

- Pneumatic lifting optional

- Heating with heating cartridge optional; Feedback of switching position optional

Vacuum valves spring-loaded

For small containers, spring-loaded vacuum valves can be used. The spring-loaded vacuum valve can also be installed in a horizontal position.

Vacuum valves weight-loaded

For large tanks, weight-loaded vacuum valves are used. These are mainly integrated directly in the tank dome lid, but can also be installed in the tank in conjunction with a weld-in flange.