M&S Dirt collecting filter

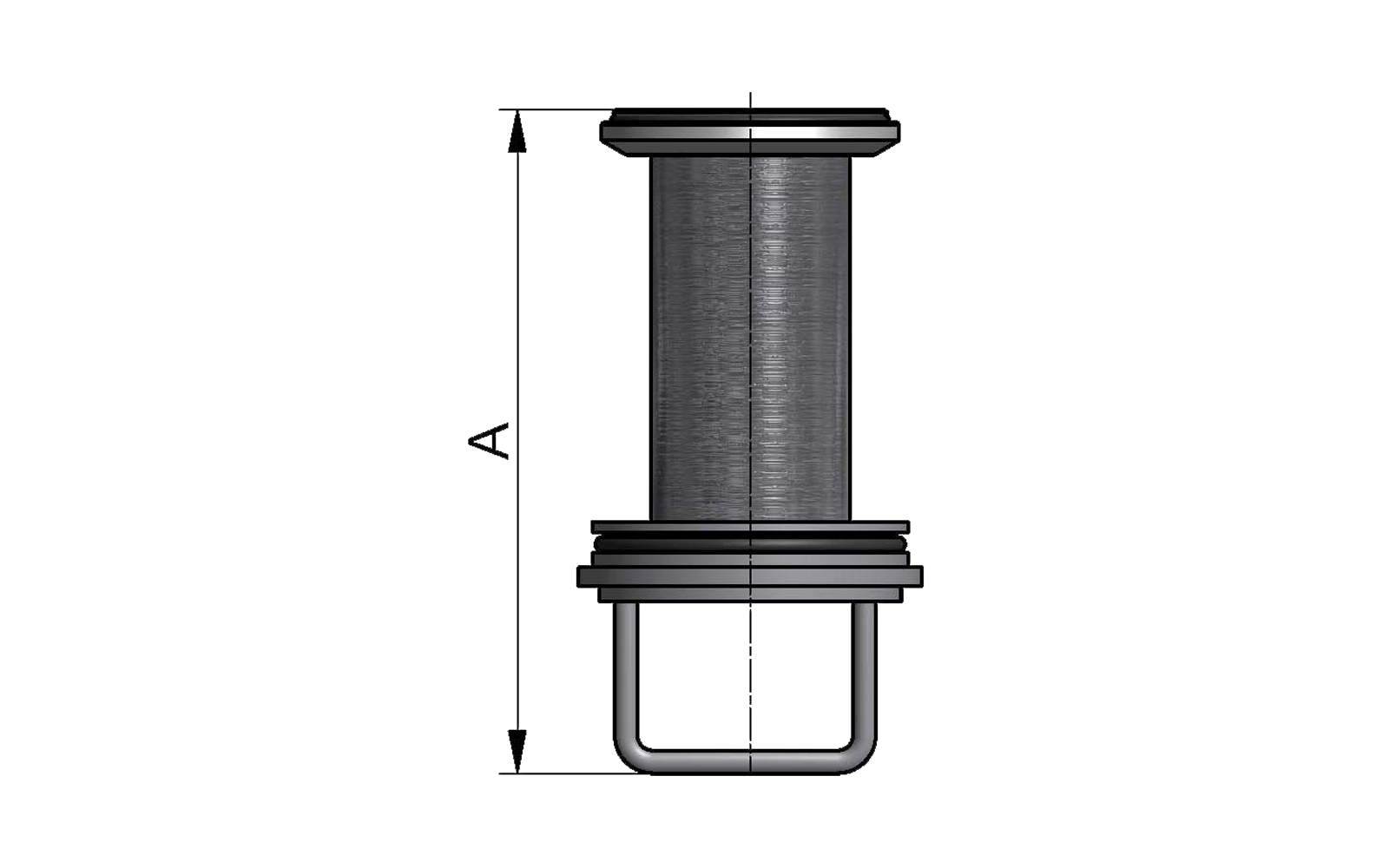

M&S dirt collecting filters are used in process plants for the filtration of liquids in a pipeline. Unwanted particles are filtered out so that downstream components are protected. Basically, they consist of a cylindrical housing with a cylindrical strainer insert made of perforated plate, gauze or slotted tube.

The open areas of the screen inserts are dimensioned in such a way that the pressure loss is as low as possible.

Features

- High flow rate due to large open area

- Flow in both direction possible with perforated plate or sandwich type

- Simple assembly and handling

- Very easy to clean and sterilise

- Cleaning of strainer without removing the housing

- Sieve body with lid and support ring fully or partially welded, depending on the version

- Stable design of the strainer insert

Same product - different combination

Screen lid

- welded type (standard)

- plugged type with o-ring sealing in the blind cover

- screwed type with round thread screwed into the blind cover

Sieve body

- perforated sheet (round holse 0,5 mm to 10 mm) optional x 10 mm

- perforated sheet with gauze (45 to 1000 my) – inside or outside, depending on flow direction

- sandwich type: combination of perforated sheet/gauze/perforated sheet

- slotted strainer from 10 my to 5000 my – flow direction from inside to outside (FITO) and optional from outside to inside (FOTI)